Zirconia Alumina

Content updated May 25, 2021

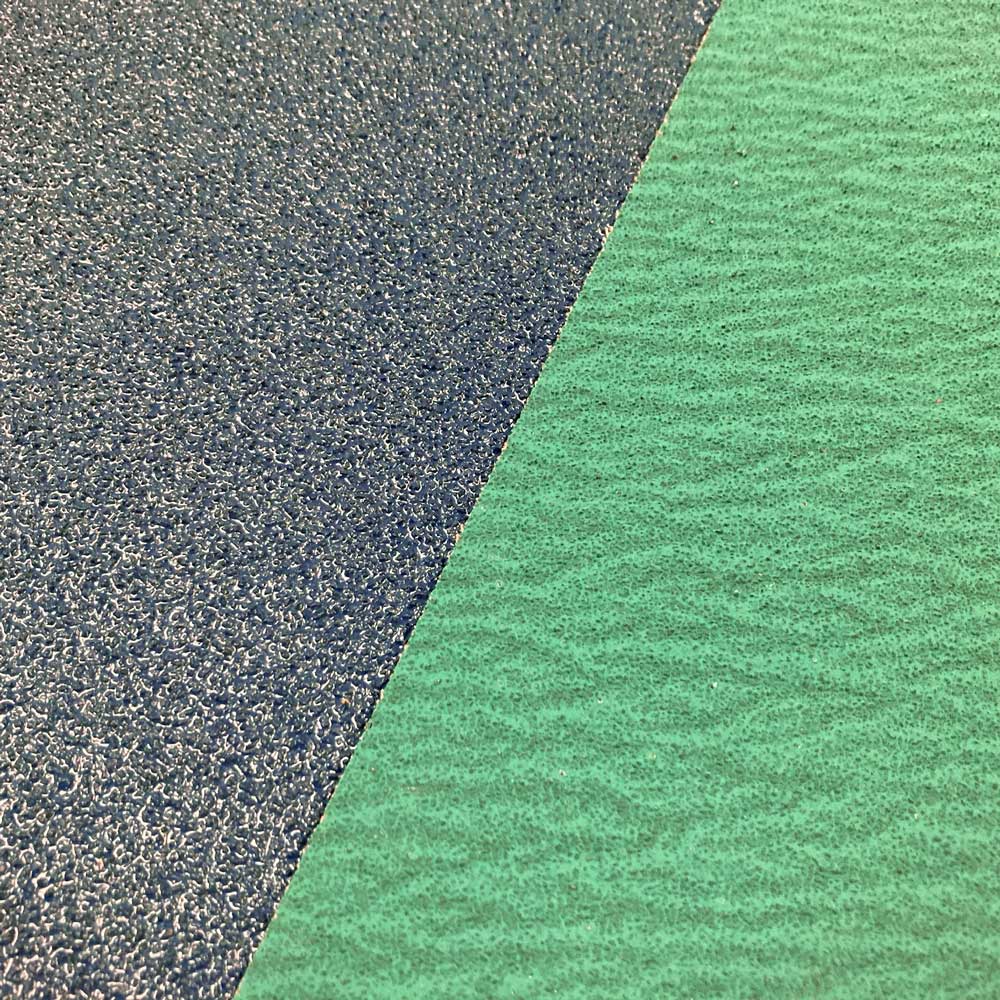

Zirconia Alumina is a high performance, alloyed abrasive grain formed by depositing zirconia in an alumina matrix. With its continuous generation of new cutting edges and an additional lubricating layer, this product combines very high stock removal with reduced temperature in the grinding zone. Benefits of this abrasive include self-sharpening characteristics, aggressive stock removal with cool cut technology and enhanced surface quality. It is an excellent choice for heavy stock removal applications.

The grain of these abrasives contains finely distributed aluminum oxide and zirconia oxide. The softer zirconia alumina is worn down first, followed by the more brittle aluminum oxide. This gradual breakdown provides a continuously new cutting edge throughout the life of the product.

Okay, now that we have the technical speak out of the way, let's look at the way you'll be using this aggressive abrasive. While Zirconia-Alumina abrasives are generally used on metal, they absolutely excel in severe grinding applications. If you're working on aluminum, stainless-steel or alloy metals, Zirconia-Alumina should be one of your go-to abrasives.

Okay, now that we have the technical speak out of the way, let's look at the way you'll be using this aggressive abrasive. While Zirconia-Alumina abrasives are generally used on metal, they absolutely excel in severe grinding applications. If you're working on aluminum, stainless-steel or alloy metals, Zirconia-Alumina should be one of your go-to abrasives.

Why Two Types?

AIS offers two types of Zirconia-Alumina abrasive belts — belts with Grind Aid Lube applied (Y3 or R203) and belts without (Y5 or R205). Why? What's the difference?

We've already described the abrasive without lube. It's a tough, dense abrasive grain that is great for heavy stock removal on metals. So, why add the lube layer to the abrasive? For one thing, the belts with grind cooler, causing less heat to build up in the piece you're working on. Since Zirconia is used most of the time on metals, it reduces the risk of burn marks on the metal.

The Grind Aid Lube is also designed to prevent the belts from loading up during use. Great news, you won't have to stop to clean the belt as often!

What About Durability?

Zirconia-Alumina belts that AIS offers have a resin bond on a Y-Weight backing. These belts are designed to be very durable. Keep in mind, though, that they will break down if they're misused. But for the most part, these belts thrive on abuse. In fact, to keep the grain sharp, they require heavy pressure while grinding.